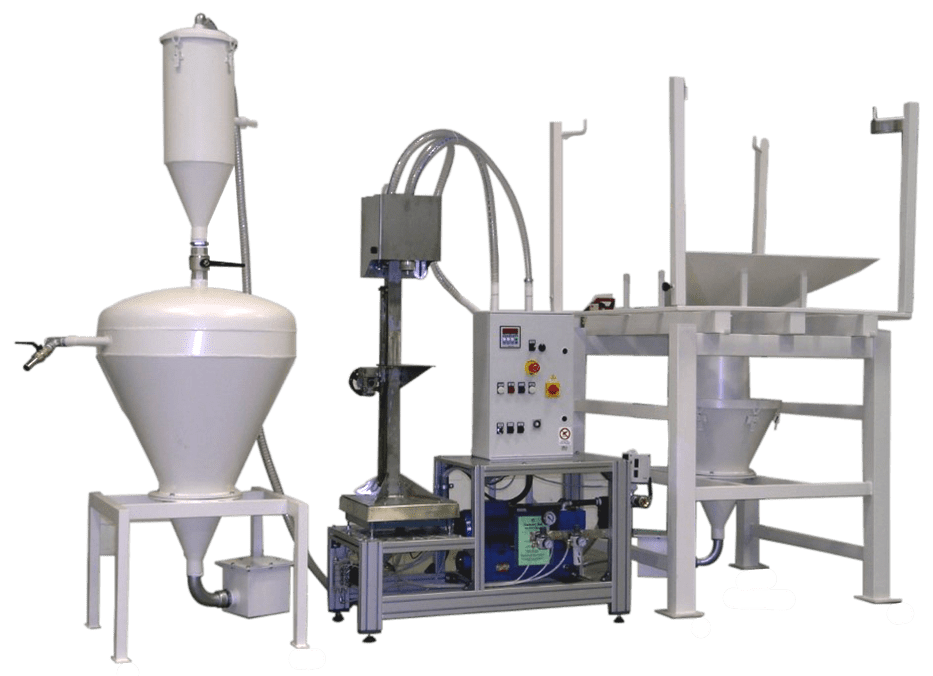

The plants MAS C series they mainly differ in the function of suctioning the dust directly from the big-bag positioned inside a containment structure and connected directly to the filling head by means of a conveyor hopper.

The system is capable of filling portable powder fire extinguishers from 1 to 12 kg and through an optional accessory (KVM), the wheeled fire extinguishers to be placed on an independent external scale, also not included.

Equipped with a dust recovery tank and empty reserve, it allows you to fill without wasting dust and its dispersion in the work environment.

COMPONENTS

- N.1 empty reserve tank and dust recovery;

- N.1 additional tank containing filter, vacuum lung;

- N.1 removable metal pallet for big-bag storage. With hopper for transferring the powder from the big-bag to the filling head;

MAS3C version:

N.1 semi-automatic filling head made of aluminum and stainless steel, containing the filling head with manual activation and advancement, electronic weighing system with display for setting weights, general electrical panel, powder passage speed 1 kg / 3 sec, vacuum pump 37 mc / h 380V 0.75 Kw

MAS2C version:

N.1 automatic filling head made of aluminum and stainless steel, containing the pneumatic activation and feed filling head, electronic weighing system with display with 99 weight memories that can be set by the user, general electrical panel equipped with PLC, nr. 02 filling programs, slow and fast with powder passage speed up to 1 kg / sec. on the fast program, vacuum pump 50 mc / h 380V 1.1 Kw.

TECHNICAL INFORMATION

Dimensions: LxPxH 3801 x 1300 x 2480 mm;

Weight: 480 Kg;

Connections required: 1 CE socket 380V 4p 16 A (5P 16A for MAS3C) plus 8 bar air.

Emptying the big bag into the tank through the hopper