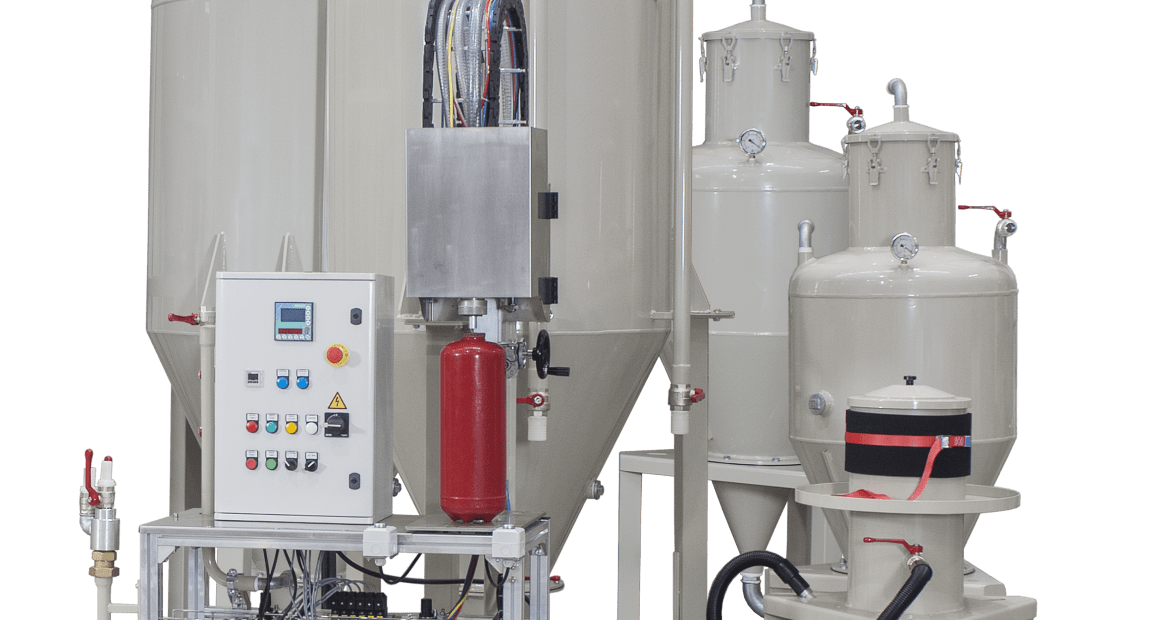

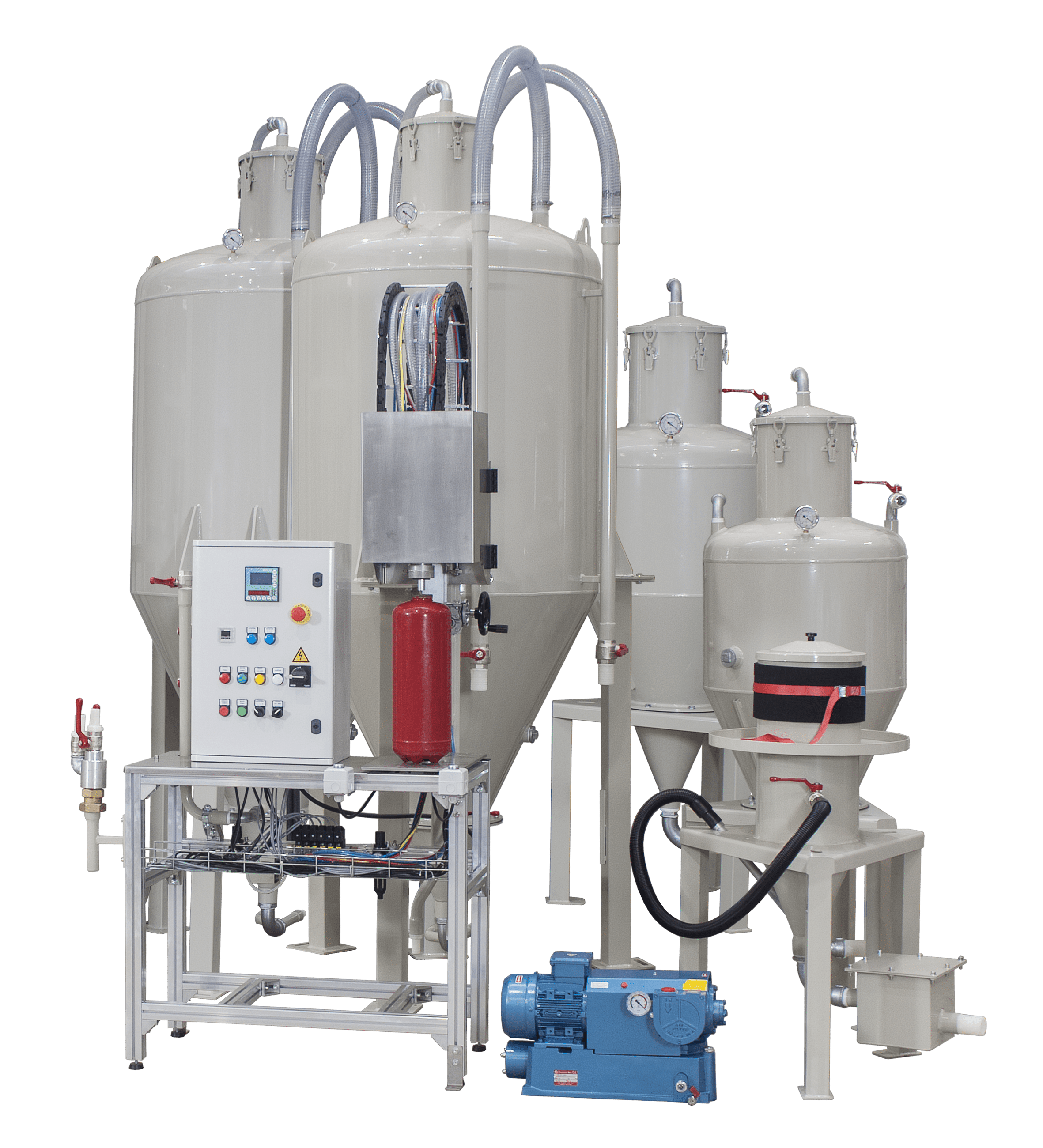

The equipment MORE 1.3D allows you to make the qualitative leap in the filling of portable and wheeled fire extinguishers from 1 to 100 kg. of capacity. There MORE 1.3D it is equipped with a double filling program, fast and slow (for maximum precision in loading small fire extinguishers). There MORE 1.3D can be integrated into an automatic fire extinguisher production line. The double powder containment tanks allow to work in a continuous phase, alternating the suction of the powder during the fire extinguisher filling phase, from one tank to the other, while one of the two tanks is being filled. Alternatively, two types of powder can be used to fill different types of fire extinguishers. The exchange of the powder used at the filling head is carried out with a pipe cleaning and cleaning system (art. PT) which prevents mixing and the possible formation of lumps between the different types of powder.

OPTIONALS:

KVMs: Venturi kit for filling wheeled fire extinguishers;

MAS HEAD: automatic head for filling wheeled fire extinguishers.

PT: Cleaning system for powder change pipes used.

COMPONENTS

- N. 2 tank, equipped with filters and painted, capacity 1000 kg. of ABC powder;

- N.1 hopper for filling the dust containment tanks, with primary dust-breaker filter and cleaning system for any accidental dust spills. The filling takes place directly from the big bag, 1000kg in about 5/10 min. with fluid powders.

- N. 2 recovery tanks - vacuum lung in painted steel

- N. 1 filling station made of aluminum and stainless steel which contains the filling head with pneumatic actuation and advancement, the electronic weighing system with 99 memories that can be set by the user, general electrical panel managed by PLC, no. 02 filling programs, slow and fast, with powder passage speed up to 1 kg / sec for the fast program, vacuum pump.

TECHNICAL INFORMATION

Dimensions: approx. LxDxH 6000x1800x3500 mm;

Empty weight: 1200 kg;

Vacuum pump 50mc / h - 380 V 1.1 Kv in oil bath;

Capacity 1000 Kg ABC powder each tank;

Filling speed: 1 kg. powder / second on the fast filling program;

Connections required: 1 CE socket 380V 4p 16 A air 8 bar.

Emptying the big bag into the tank through the hopper